About Us

Italian brand with a 50-year history

Innovative business with great competitive advantages and low costs through which you can achieve high turnover and profit

Our History

We started our family business many years ago as the fashion industrial production has just begun. At first, we started small, but shortly after we increased our production team significantly. We had been producing fashion collections for many elite brands from Italy, France, Germany and other countries when we saw the missing piece in the industry.

Our team was trained by leading fashion technologists and prioritized the well-being and growth of its employees, fostering a culture of trust, collaboration, and mutual respect. They celebrated each other's successes, supported one another through challenges, and forged deep personal bonds that extended beyond the office walls.

We build our own production facility of 20.000 sq.m. to be able to meet our production needs. We started the development of Made-to-measure innovative system and created a large international network of partners.

Our partners were not only boutique shops, but also entrepreneurs and young designers, which we trained for business development. Over the years we have held many business conferences and fashion shows to help our partners grow their business.

During the years, we created strong collaborations with Italian partners which lead us to the Italian historical brand Cantarelli.

Cantarelli is a Italian brand with a 50-year history. In the past, over 900 employees worked at the production. For many years, Cantarelli’s factory has produced the collections of world-renowned luxury brands, thus developing its know-how, some of which are: Gucci, Alexander McQueen, Celine, Luis Vuitton, Chanel, Balmain, Victoria Beckham, Philippe Plain, Christian Dior.

Today, we are focused on:

- Cantarelli Fabrics Selection - a rich variety of luxury fabrics produced by leading Italian mills

- See Now-Buy Now & Made-to-Measure production of clothing collections with a short production time of 5 -10 working days

- Full Made-to-measure on traditional Italian technology

Cantarelli is one of the best companies in the world to deliver Made-To-Measure high quality men garments.

Our Vision

For the past few years we have been working with business consultants to develop the best system for the fashion industry. A system which gives benefits to all participants of the production chain – fabric mills, accessory manufactures, garment manufacturing, retail, final customer.

Our partners were not only boutique shops, but also entrepreneurs and young designers, which we trained for business development. Over the years we have held many business conferences and fashion shows to help our partners grow their business. Our goal is to work together to create business added value within a trustable relationship.

Ethical Fashion

Cantarelli is reshaping the manufacturing process towards transparency and sustainability practices.

Our main goal is to contribute to the promotion and implementation of Ethical fashion and the new regulations of the European Commission.

Full transparency of production and sales

ESPR - Ecodesign regulations for sustainable products CSDD - Corporate sustainability Due Diligence Directive

Stop exploiting people!

The fashion industry is the first in terms of exploitation. Over 90% of the products sold in Europe are produced in the Near and Far East without transparency of production. * Cantarelli offers products with 100% EU production in standardized ethical factories for all labor and materials put into the product.

Sales of valuable products only!

The majority of products that are available in Europe are made from cheap materials with low technology and huge overcharges to end customers - from the cost of the product to the price in the store is 10-15 times rise. * Cantarelli offers value products to stores, which can be ordered directly from the factory at a fair price by eliminating commissioners, leftover product’s costs and losses from lost sales.

Stop polluting the nature!

The fashion industry is among the three most polluting industries. A huge part of the products sold in Europe are made from polyester fabrics. * Cantarelli offers production only from high quality materials produced in certified Italian factories.

Service

The European Commission requires warranty and out-of-warranty service. The majority of products available in Europe have a very short life cycle due to poor materials and production technology. *Cantarelli offers products with only natural materials, produced according to traditional Italian technology in renowned European factories, which ensure a long life of the clothes.

Responsibility of the end customer

The European Commission already requires responsibility from the end customer. By buying unethical products, the customer supports exploitation and pollution. End customers are now much more demanding and critical of the products they buy. Customers are now interested in provenance:

-

Where and in which factory was my garment made and were the ethical standards for the workers respected?

-

What materials and fabrics is my garment made of and is it environmentally friendly?

More than 95% of the clothes sold in the EU market do not have labels showing: the factories where they were produced it and the fabrics and materials used.

Production

Preservation

of Italian production technology in combination with high-tech machines

100% EU production

European certificates for all materials used in the production of the suit

BSCI standard

for ethical production

Green energy

supplied by solar panels

European funding

The factory was developed with the support of European funding to preserve and create new jobs in Europe

New modern production building

20.000 sq.m.

Annual capacity

250.000 garments

CAD-CAM - Lectra, France

order processing and optimization software

25 cutting robots for single orders

Lectra, France

Sewing line

use of the most modern sewing machines and ironing presses - Durkopp, Pfaff, Strobel, Brisay, Veit

Production transport

Eton Transport Systems, Sweden - Achieving efficiency while simultaneously working with different models, technologies and leadtimes

Cantarelli's customers:

- Fashion brands from Italy, France, Germany, Great Britain, America and other countries

- Made To Measure boutiques from over 20 countries

Products

Possibility to cover all targets and price groups on the market

- Garment lines Men's; Women's; Children's

- Product types Suits; Jackets; Trousers; Vests; Coats; Skirts

- Styles Ceremonial; Classic; Business; Casual

- Production lead time 5 - 10 working days

- Technology full canvas, half canvas, fused

- Possibility for private label and co-branding

Ordering process

- Easy system for taking measurements we will provide you a full training and support in time

- Easy ordering system we will provide you a full guide on how to work with the order form and will support you in time

From all fits, models, fabrics and designs you can offer your customer more than 1 million combinations.

The system allows you to spend less time on the order so you can focus on business development.

Our company offers a complete package which includes all men’s wear manufacturing services from start to finish.

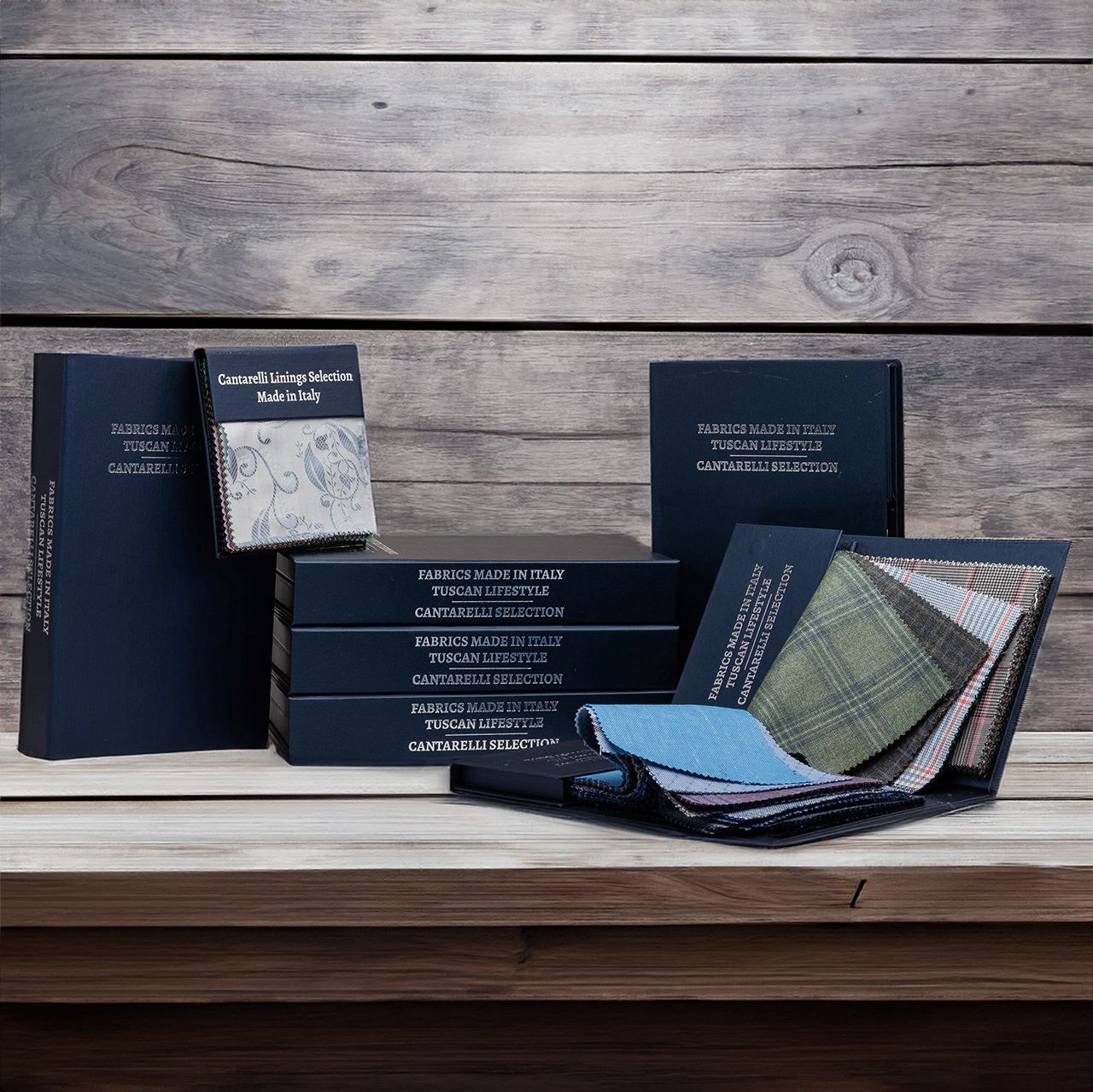

Cantarelli Fabrics Selection

Huge variety

over 5000 exclusive Italian fabrics in stock

Fabric categories

ceremonial, classic, casual

Fineness of fabrics

100S - 170S in different weights

Fabric composition

100% wool, silk, linen, cashmere, and mixtures

Coverage of all price groups divided in categories

12 collections a year

ongoing new offers

Selection of fabrics

100% made in Italy, by world-famous Italian fabric mills:

- Vitale Barberis Canonico,

- Lanificio Cerruti,

- E.Thomas,

- Carlo Barbera,

- Lanificio Colombo,

- Lanificio TG di Fabio,

- Ferla,

- Piacenza,

- Loro Piana,

- Maggia,

- Gruppo Dondi and other.

The selection was created by Tuscan designers with many years of experience in creating collections for world-famous luxury brands.

Contact Us

Innovative business with great competitive advantages and low costs through which they are achieved high turnover and profit.

Start a partnership with Cantarelli!

For further information and queries, you can reach out to us. Our team can guide you about our production services, competitive costing, and other details.

+39 338 433 2367

+359 888 39 39 39

+359 888 93 93 93

ceo@cantarellituscanlifestyle.it

B2B Sales central office – World Fashion Centre Kon. Wilhelminaplein 13, 1062 HH Amsterdam, Netherlands

Design headquarters – Cortona, Tuscany, Italy Italy, AR, Terontola, 52044, SR142.